Photo Etched Film for Precision Filtration

Photo Etched Film

It adopts chemical etching process to process various complex shapes of high-precision mesh and graphic on various metal sheets according to the designed geometric figures, which cannot be completed by various mechanical processing methods.

Material

Stainless steel sheet, copper sheet, aluminum sheet and various alloy sheets.

The Principle Of Etching

Etching is also called photochemical etching. It refers to plate making through exposure, after development, the protective film of the area to be etched is removed, and the etching site is contacted with a chemical solution to achieve the effect of dissolution and corrosion to form the required shape and size.

Production Process

① Cut the metal plate according to the requirements of the drawing.

② Design graphics on the metal plate.

③ Prepare or choose different chemical solutions according to different materials.

④ Cleaning plate-inking-drying-exposure-development-oven drying-etching-ink removal-cleaning and drying.

Technical Standard

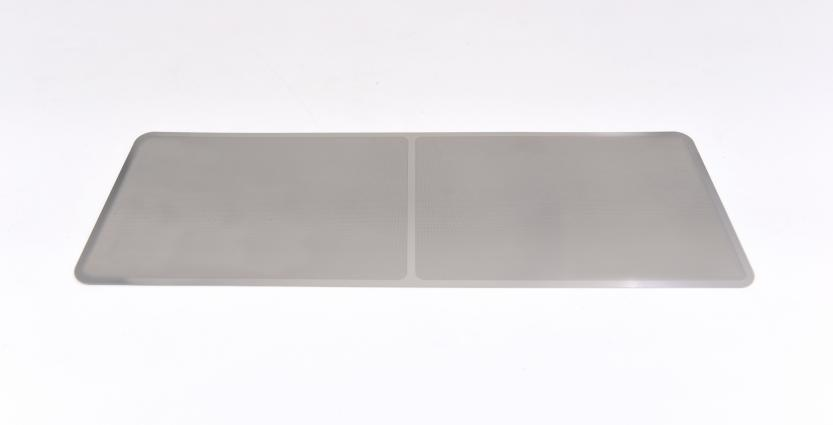

① Etching area: 500mmx600mm.

② Material thickness: 0.01mm-2.0mm, especially suitable for ultra-thin plates below 0.5mm.

③ Minimum wire diameter and minimum hole diameter: 0.01-0.03mm.

(1) Micropores are round holes

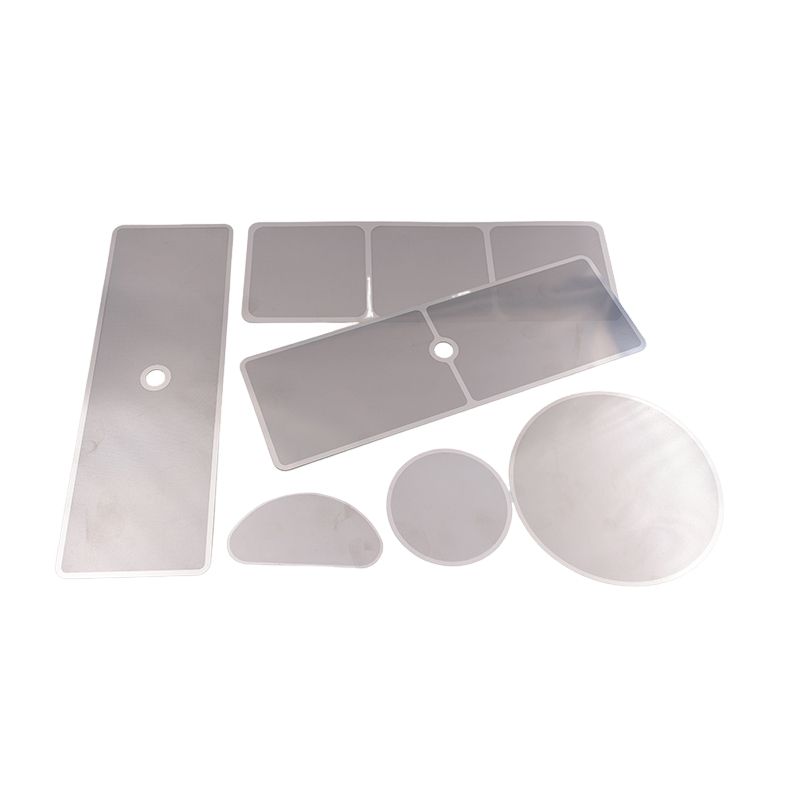

Classified by the shape of photo etched plate: round, semicircular, rectangular, etc.

Classified by the thickness of photo etched plate: 0.05mm, 0.08mm, 0.1mm, 0.12mm, 0.15mm, etc.

Different specifications and sizes can be processed according to customer requirements.

(2) Micropores are waist shaped pores

Classified by the shape of photo etched plate: round, semicircular, rectangular, etc.

Classified by the thickness of photo etched plate: 0.05mm, 0.08mm, 0.1mm, 0.12mm, 0.15mm, etc.

Different specifications and sizes can be processed according to customer requirements.

Features

① High precision.

② Processing various complex micro-hole patterns.

③ Processing various small and thin products.

Uses

Photo etched film can be used in precision filter mesh, filter plate, filter cartridge and filter in petroleum, chemical, food, pharmaceutical and other industries.