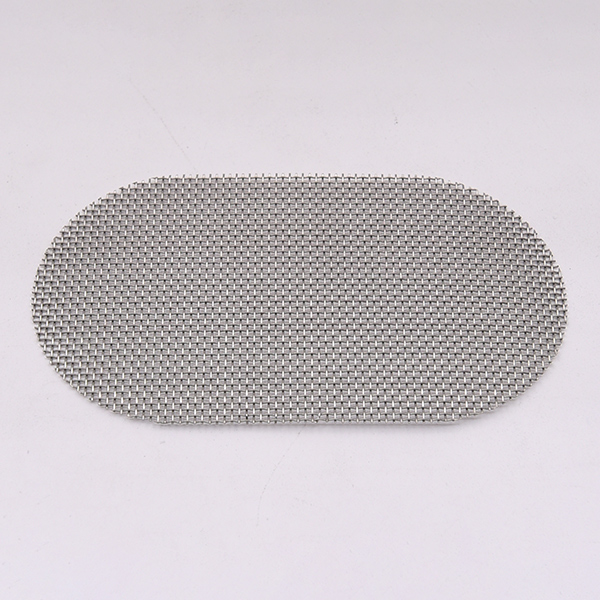

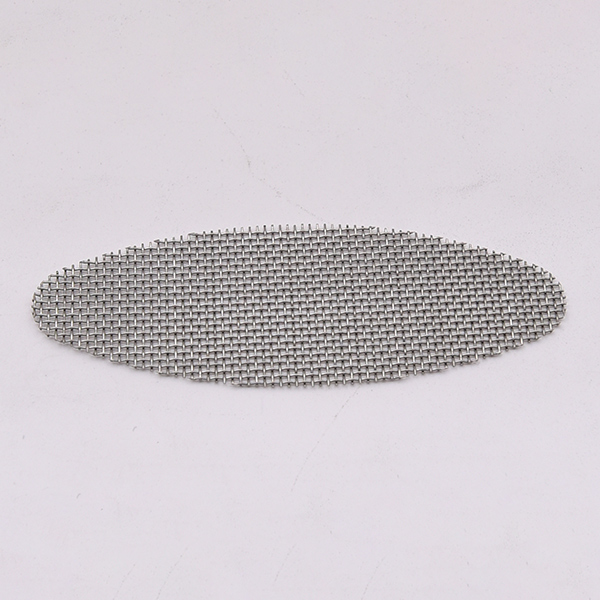

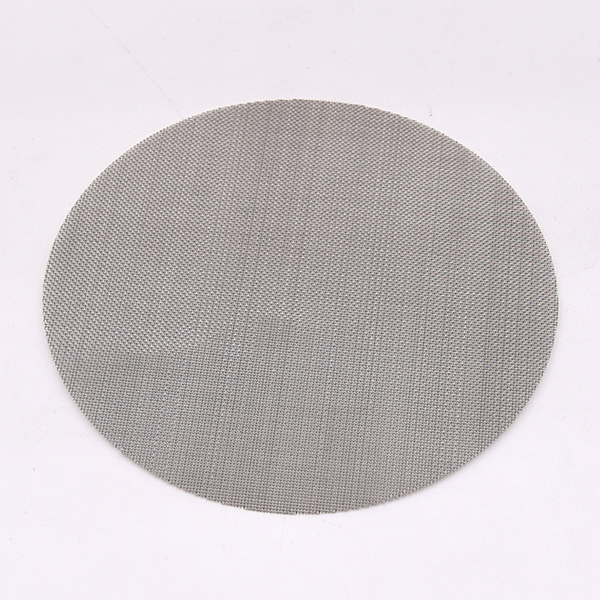

Stainless Steel Filter Screen

Filter Screen

Process the metal mesh or sintered fiber into filters of various specifications and shapes by stamping, laser cutting, forming and other methods, It is mainly used in distillation, absorption, evaporation, filtration and other processes in rubber, plastic industry, grain and oil screening, petroleum, oil refining, chemical industry, light industry, medicine, metallurgy, machinery, ships, automobile tractor and other industries. At the same time, it can also be used to eliminate mist and liquid entrained in steam or gas, and as an air filter in automobiles.

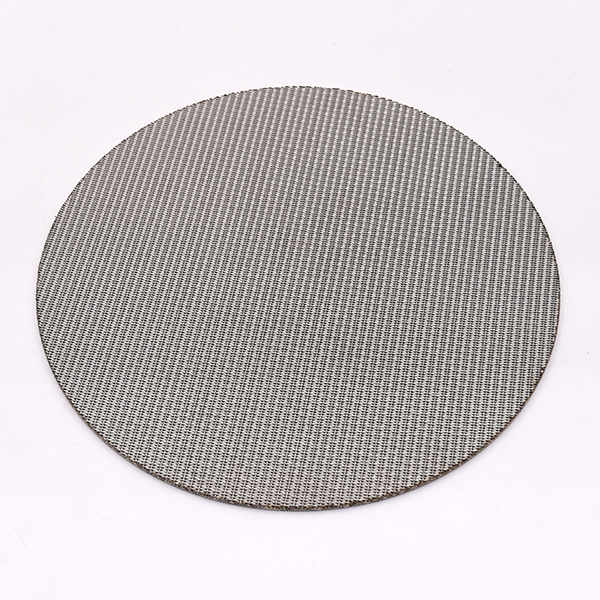

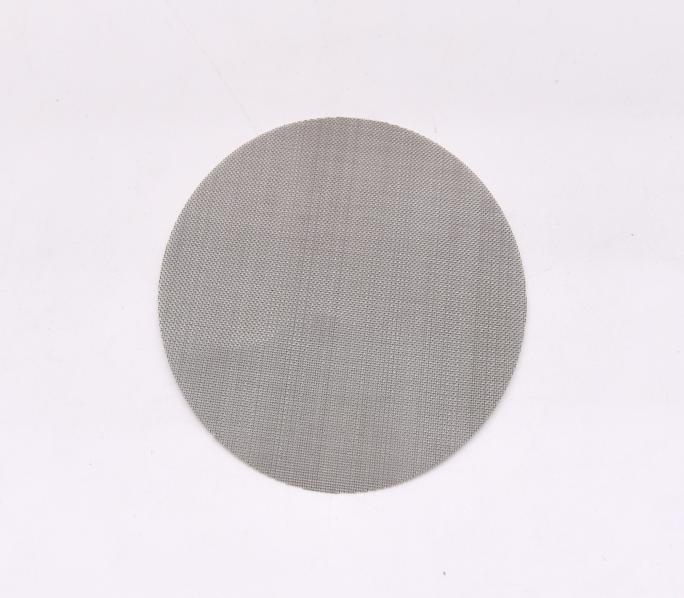

Flat Surface

The screen surface of this Filter screen is flat

Classified according to the shape of filter screen: round, rectangular, semicircular, waist-shaped, hollow, special-shaped (with pictures)

Classified by the number of layers: single layer, multi-layer (spot welding) (with pictures)

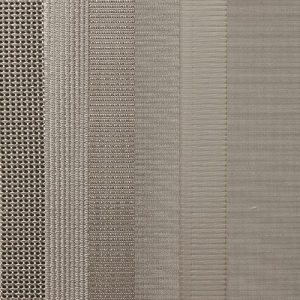

Classified by main filter layer: sintered fiber, dutch weave, wire mesh.

★ The external dimensions and the number of filter mesh layers can be customized according to actual needs.

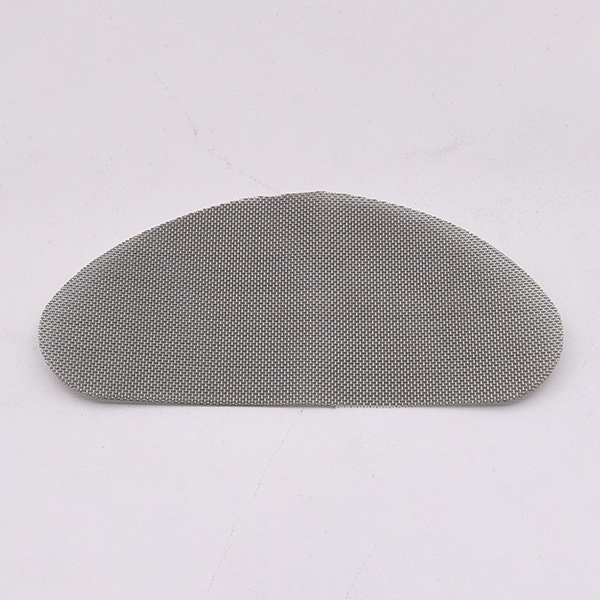

Bowl

The shape of this pack filter is bowl.

Classified by the shape of filter screen: round, rectangular, semicircular, waist-shaped.

Classified by the number of layers: single layer, multi-layer (spot welding).

★ The external dimensions and the number of filter mesh layers can be customized according to actual needs.

Sintered Filter Screen

It is a filter screen processed from various specifications of sintered mesh

(1) Five-layer sintered Filter screen: Five layers of stainless steel wire mesh are stacked together according to different structures, and then made into porous sintered materials through processes such as sintering, pressing, and rolling. We process meshes of different shapes and sizes according to customer needs. (with pictures)

(2) Multi-layer square hole sintered Filter screen: The sintered mesh made of multi-layer plain woven square hole mesh has the characteristics of high air permeability, low resistance and large flow rate due to the high opening rate of the square hole mesh. According to customer needs, it is processed into meshes of different shapes and sizes. (with pictures)

(3) Perforated plate sintered Filter screen: Perforated plate and multi-layer stainless steel wire mesh are sintered. Due to the support of the perforated plate, the compressive strength and mechanical strength of the sintered mesh are higher. According to customer needs, it is processed into meshes of different shapes and sizes. (with pictures)

(4) Dutch weave sintered filter screen: It is a sintered mesh made by stacking two or three layers of flat-woven dense meshes of the same precision and crossed together through sintering, pressing, rolling and other processes. It has the characteristics of uniform mesh distribution and stable air permeability. According to customer needs, it is processed into meshes of different shapes and sizes. (with pictures)

Mesh Cylinder

The metal mesh of different specifications is processed into a cylindrical shape by rolling, welding and other processes.

Classified by the filter medium: metal mesh, dutch weave, sintered fiber.

Classified by the number of layers: single layer, multi-layer.

Classified by the shape of the mesh surface: plane, pleated.

Compression Mesh Washers

Wire mesh compression Washer is a special form of knitted mesh product.it is Used in the manufacture of wire mesh demisters, oil and gas separators, dust removal and environmental protection; separation and filtration devices for various occasions; filter elements for automobiles and tractors; sealing, shock absorption (shock absorption), noise reduction and exhaust in auto parts Purification components; electromagnetic interference shielding devices for electronic and electrical products.

Performance Characteristics

(1). High temperature resistance, large temperature difference resistance, radiation resistance, corrosion resistance

(2). Strong load-bearing capacity, high load, anti fatigue, no aging phenomenon, and long service life.

(3). It can meet the requirements of damping, shock absorption, filtering, sealing and throttling. It is a substitute for ordinary rubber products and other porous material products under special working conditions.

Material

SUS304, SUS316, nickel, titanium, copper, etc.

Product Shape

Round, square, cylindrical, ring, etc. (with pictures).

Product Display