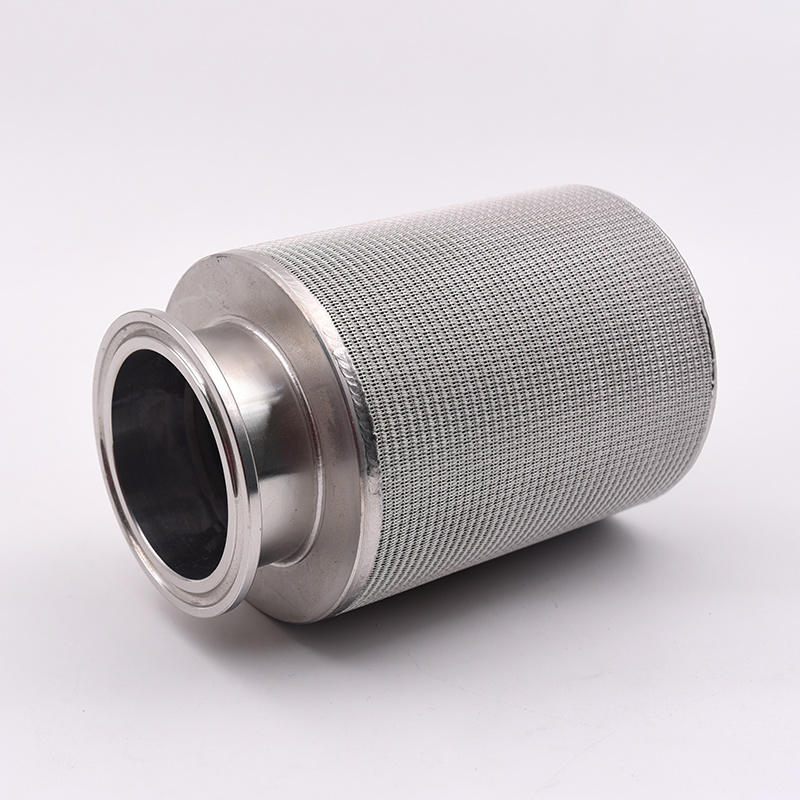

Sintered Wire Mesh Candle Filter

Sintered Wire Mesh Filter

The sintered wire mesh filter is a new type of filter material made by vacuum sintering with high mechanical strength and overall rigidity. The mesh holes of each layer of the sintered mesh filter element are interlaced with each other to form a uniform and ideal filter structure. This material has advantages that ordinary metal mesh cannot match, such as high strength, good rigidity, and mesh shape. Stable etc. Because the void size, permeability and strength characteristics of the material can be reasonably matched and designed, it has excellent filtration accuracy, filtration resistance, mechanical strength, wear resistance, heat resistance and processability, and its comprehensive performance is obvious Superior to other types of filter materials.

Sintered Mesh Structure and Characteristics

Multi-layer sintered mesh is generally divided into a five-layer structure, which is divided into four parts: protective layer, filter layer, separation layer and support layer. This kind of filter material has both uniform and stable filtration precision and high strength and stiffness, which can withstand pressure. It is an ideal filter material for occasions with high strength requirements and uniform filter particle size. Because its filtration mechanism is surface filtration and the mesh channels are smooth, it has excellent backwash regeneration performance and can be used repeatedly for a long time. It is especially suitable for continuous and automated operation processes. Sintered mesh is easy to shape, process and weld, and can be processed into various forms of filter elements such as circular, cylindrical, and cone-shaped.

Characteristics of Sintered Mesh Filter Element

1. The standard layer network consists of a protective layer, a precision control layer, a dispersion layer and a multi-layer reinforcement layer;

2. High strength: After sintered, the wire mesh has extremely high mechanical strength and compressive strength;

3. High precision: It can exert uniform surface filtration performance for filtration particle sizes of 2-200um;

4. Heat resistance: durable in continuous filtration from -200 degrees to up to 650 degrees;

5. Cleanability: Due to the surface filtration structure with countercurrent cleaning effect, cleaning is easy.

Product Application Scope

1. Used as dispersing cooling material in high temperature environment;

2. Used for gas distribution, liquid bed orifice plate material;

3. Used for high-precision, high-reliability and high-temperature filter materials;

4. Used for high-pressure backwashing of oil filters.

5. Precision filtration of various hydraulic oils and lubricants in the machinery industry;

6. Filtration and purification of various polymer melts in the chemical fiber film industry, filtration of various high-temperature and corrosive liquids in the petrochemical industry, filtration, washing and drying of materials in the pharmaceutical industry;

Product Interface Mode

Standard interface (such as 222, 220, 226), quick interface connection, threaded connection, flange connection, tie rod connection, special customized interface.

Product Application Industry

Sintered mesh filter elements are widely used in the filtration of polyester, water treatment, oil products, pharmaceuticals, food and beverages, chemicals, chemical fiber products, and the filtration of high-temperature air and other media. Due to the large surface area of the sintered mesh filter element, small size, high efficiency, and easy maintenance It has the unique advantage of being able to filter dust that absorbs moisture and has a high water content, as well as filtering oil and fiber dust. It is suitable for operating situations where the gas contains water and oil.