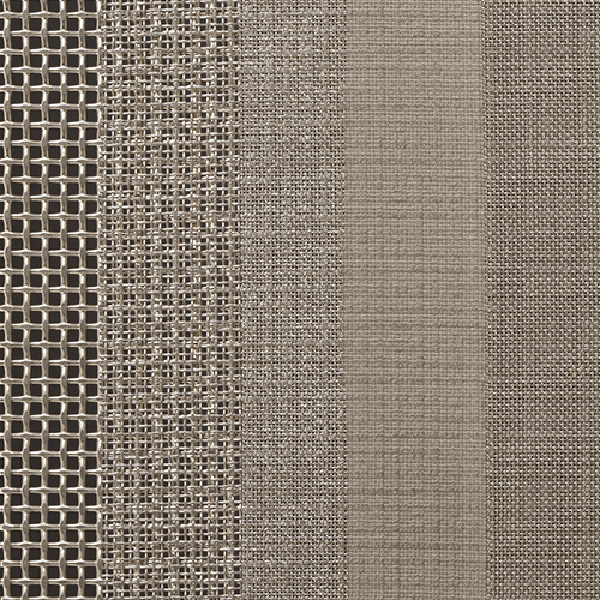

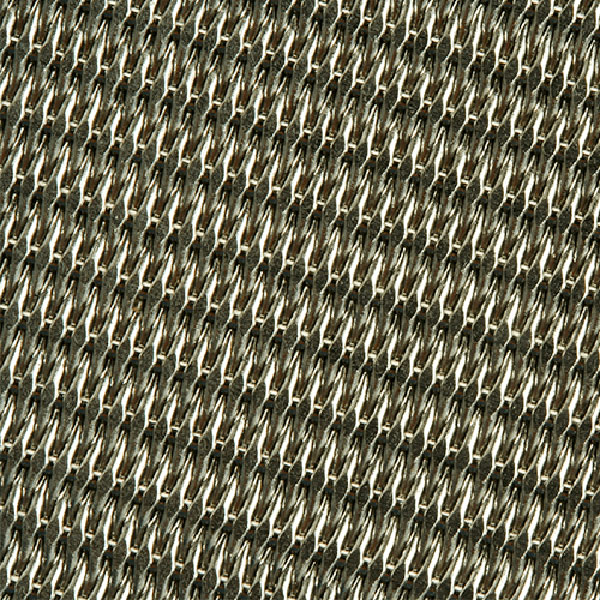

Sintered Metal Wire Mesh in Multiple Layers

Sintered Mesh

A new type of filter material is made from multi-layer metal woven wire mesh through special lamination pressed and vacuum sintered processes.It has high mechanical strength and a rigid overall structure.

The mesh holes of each layer of the wire mesh are interlaced to form a uniform and ideal filtration structure. This material overcomes shortcomings of low strength, poor rigidity, and unstable mesh shape of ordinary metal wire mesh. And it can reasonably match and design the pore size, permeability, and strength characteristics of the material. so that it has excellent filtration accuracy, filtration resistance, mechanical strength, wear resistance, heat resistance and processability. The comprehensive performance is significantly superior to other types of filter materials such as sintered metal powder, ceramics, fibers, filter cloth, filter paper, etc.

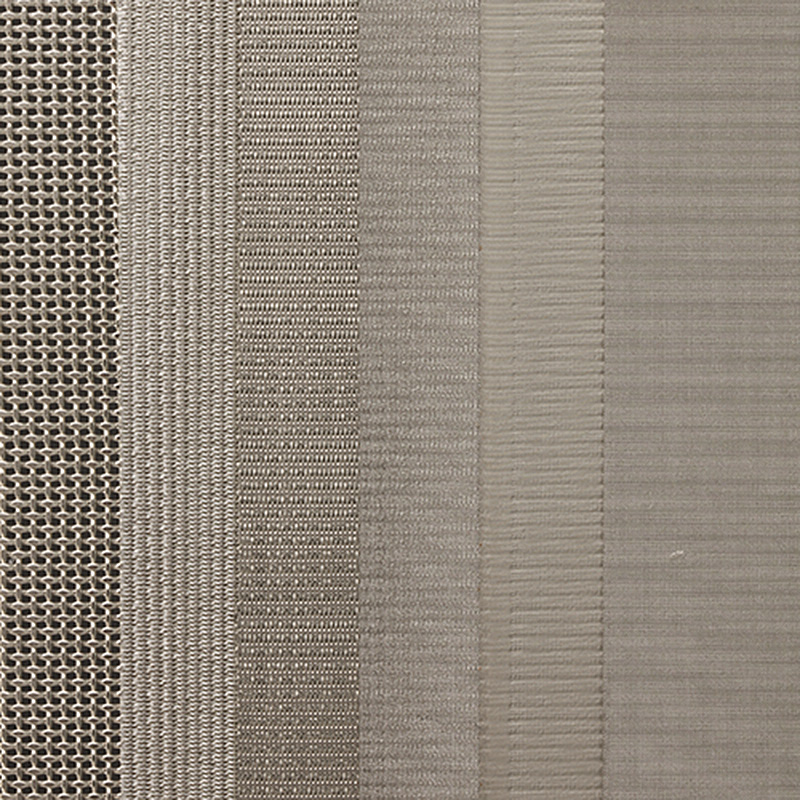

① Five-layer Sintered Mesh

It is a porous sintered material made by stacking five layers of stainless steel wire mesh with different structures together, and then undergoing processes such as sintered, compression, and rolled.

Features

(1)Wide range of filtration accuracy: from 1μ-100μ, all have reliable filtration performance;

(2) Stable filtration accuracy: Due to the upper and lower layers of wire mesh for protection, the mesh of the filter layer is not easily deformed;

(3) High strength: With the support of the fourth and fifth layers, it has inherent high pressure resistance and mechanical strength.

(4) Easy to clean: Due to the use of surface filtration materials, it has the characteristic of easy cleaning and is particularly suitable for backwashing;

(5) High temperature resistance: It can withstand high temperatures up to 480℃.

(6) Corrosion resistance: Due to the use of stainless steel and special alloy materials, it has high corrosion resistance.

(7) Easy to process: suitable for cutting, bending, stamping, stretching, welding and other processing conditions.

Materials

SUS304, SUS316, Hastelloy, Monel, Inconel, duplex stainless steel, and other special alloys.

Standard Size

500*1000mm, 600*1200mm, 1000*1000mm, 1200mm*1200mm, 1200*1500mm. Sizes within the above range can be customized according to user requirements.

Technical Parameters

| Model | Nominal Filtration | Structure | Air permeability(L/min/cm²) | Bubble pressure(pa) |

| FTA5-1 | 1 | 100/400x2800/100/12x64/64x12 | 1.81 | 5300-6000 |

| FTA5-2 | 2 | 100/325x2300/100/12x64/64x12 | 2.35 | 4300-5000 |

| FTA5-5 | 5 | 100/200x1400/100/12x64/64x12 | 2.42 | 3000-3700 |

| FTA5-10 | 10 | 100/165x1400/100/12x64/64x12 | 3 | 2700-3300 |

| FTA5-15 | 15 | 100/165x1200/100/12x64/64x12 | 3.41 | 2000-2600 |

| FTA5-20 | 20 | 100/165x800/100/12x64/64x12 | 4.5 | 1800-2300 |

| FTA5-25 | 25 | 100/165x600/100/12x64/64x12 | 6.12 | 1400-1900 |

| FTA5-30 | 30 | 100/450/100/12x64/64x12 | 6.9 | 1200-1700 |

| FTA5-40 | 40 | 100/325/100/12x64/64x12 | 7.2 | 1000-1500 |

| FTA5-50 | 50 | 100/250/100/12x64/64x12 | 8.41 | 900-1200 |

| FTA5-75 | 75 | 100/200/100/12x64/64x12 | 8.7 | 700-1100 |

| FTA5-100 | 100 | 100/150/100/12x64/64x12 | 9.1 | 650-1000 |

Application Fields

Petrochemical, polyester, pharmaceutical, food and beverage, chemical, water treatment, hot gas filtration,crude oil process, ventilation & air filtration ,power plant,metallurgical industries, etc.

Application Products

Sintered Filter, leaf disc filter, pack filter,filter disc,basket filter,Cylindrical filter,etc.

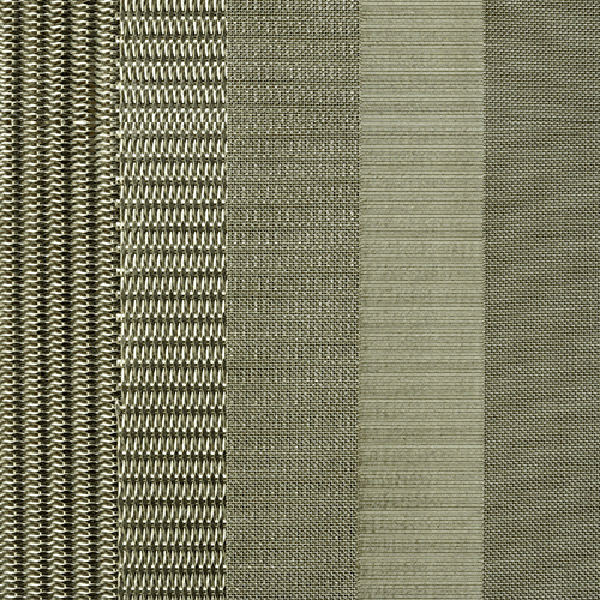

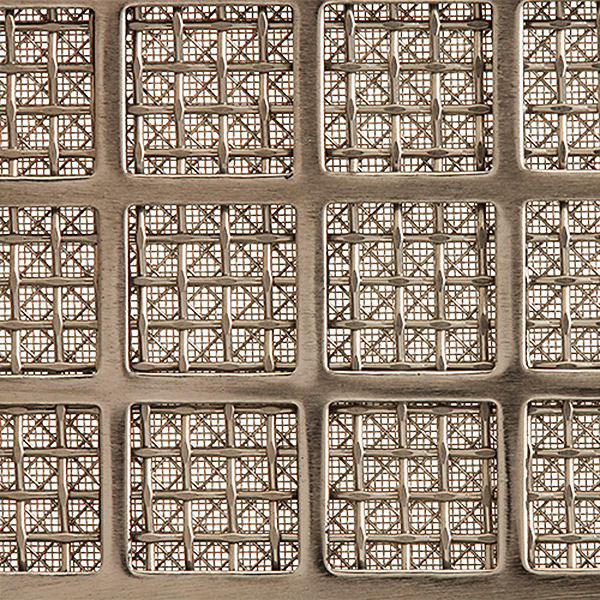

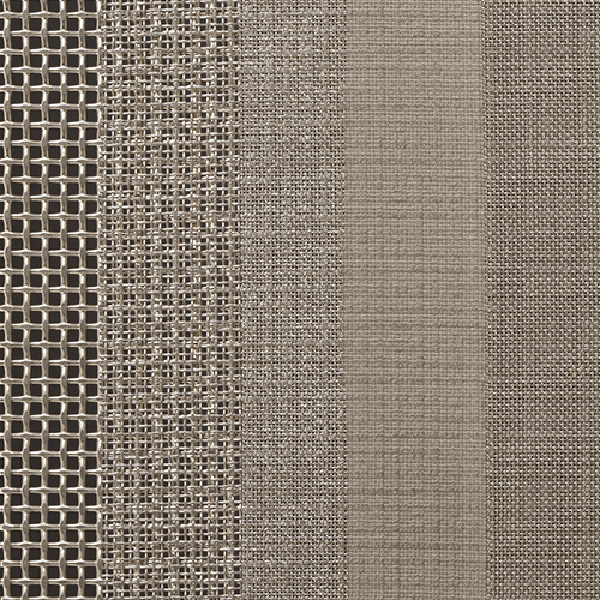

② Multi-Layer Square Hole Sintered Mesh

The sintered mesh made of multi-layer plain woven square hole mesh has the characteristics of high air permeability, low resistance and large flow rate due to the high opening rate of the square hole mesh. Mainly used in the filtration of various gases and liquids. Since each layer of screen has greater selectivity, its structure can be customized according to user requirements.

Material

SUS304, SUS316, Hastelloy, Monel, Inconel, duplex stainless steel and other special alloys.

Standard Size

500*1000mm, 600*1200mm, 1000*1000mm, 1200mm*1200mm, 1200*1500mm. Sizes within the above range can be customized according to user requirements.

Technical Parameters

| Model | Structure | Filter precision | Thickness(mm) | Porosity (%) |

| FTB2-0.5T | filter layer/60 | 2-100 | 0.5 | 60 |

| FTB3-0.7T | 60/filter layer/60 | 2-100 | 0.7 | 56 |

| FTB3-1.0T | 50/filter layer/20 | 20-200 | 1 | 58 |

| FTB3-2.0T | filter layer/20/8.5 | 20-250 | 2 | 58 |

| FTB4-1.0T | 60/filter layer/40/20 | 2-200 | 1 | 44 |

| FTB4-1.7T | 40/filter layer/20/16 | 2-200 | 1.7 | 54 |

| FTB4-1.8T | 24x110/filter layer/20/16 | 2-200 | 1.8 | 46 |

| FTB5-1.9T | 30/filter layer/60/20/16 | 2-200 | 1.9 | 52 |

| FTB5-2.5T | 80/filter layer/30/10/8.5 | 2-200 | 2.5 | 55 |

| FTB7-2.0T | 50/filterlayer/40/20/40/filter layer/50 | 2-150 | 2 | 58 |

Note:

(1). As long as the filter precision is within our specified range, the filter layer is determined by the customer.

(2). We can produce sintered mesh with special structure according to customer's requirements.

(3). We take 40 micron filter layer as our standard.

Application Fields

Air, water and oil filtration, sand control filter for oil & gas, green hydrogen, filtration for refine process,nuclear energy, etc.

Application Products

Sintered wire mesh filter, filter for film, pack filter, filter disc, basket filter, Cylindrical filter, etc.

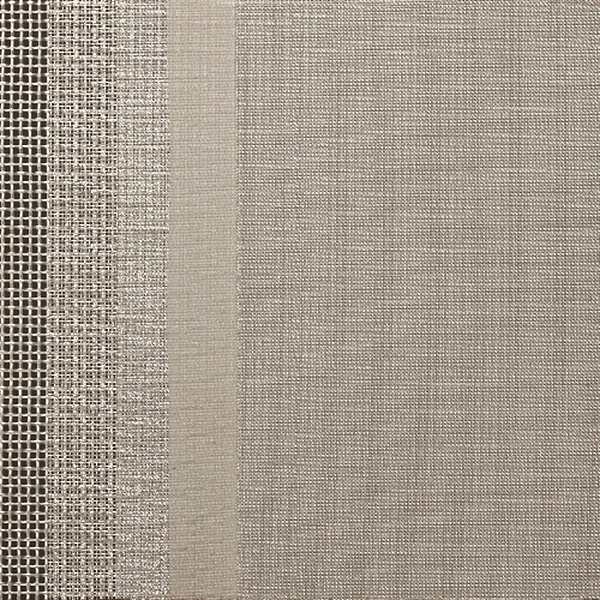

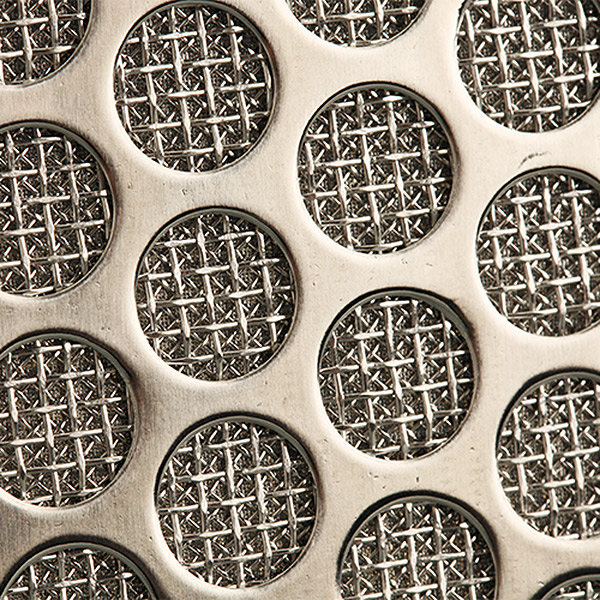

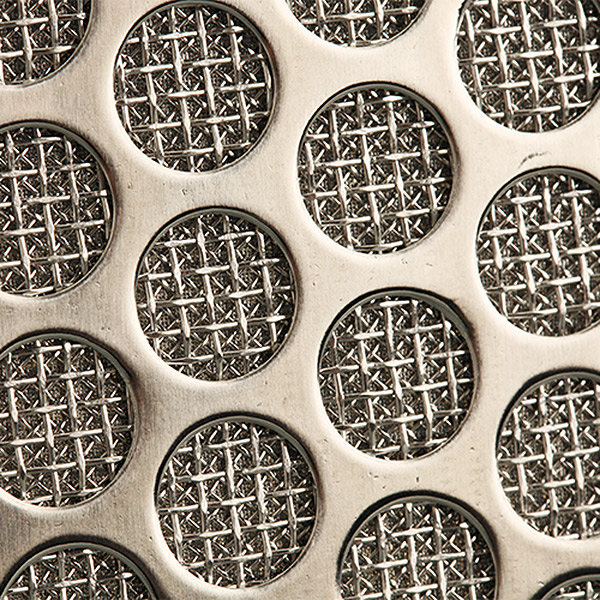

③ Perforated Plate And Multi-Layer Stainless Steel Wire Mesh Sintered

Due to the support of the perforated plate, the sintered mesh has higher compressive strength and mechanical strength. It is mainly used in industries such as food and beverage, water treatment, power plant dust removal, pharmaceuticals, and membranes. It can be processed into cylindrical, disc-shaped, and sheet-type filters. The thickness of the perforated plate and the structure of the wire mesh can be customized according to user requirements.

Material

SUS304, SUS316, Hastelloy, Monel, Inconel, duplex stainless steel and other special alloys.

Standard Size

500*1000mm, 600*1200mm, 1000*1000mm, 1200mm*1200mm, 1200*1500mm. Sizes within the above range can be customized according to user requirements.

Technical Parameters

| Model | Structure | Filter precision | Thickness(mm) | Porosity (%) |

| FTC4-2.0T | 30/filter layer/30/φ4x5Px1.0T | 2-200 | 2 | 57 |

| FTC4-2.5T | 30/filter layer/30/φ5x7Px1.5T | 2-200 | 2.5 | 50 |

| FTC4-1.5T | 60/filter layer/30/φ1.5x3Px1.0T | 2-200 | 1.5 | 30 |

| FTC5-3.0T | 60/filter layer/60/20/φ6x8Px2.0T | 2-200 | 3 | 50 |

| FTC5-4.0T | 20/filter layer/20/10/φ8x10Px2.5T | 2-200 | 4 | 55 |

| FTC5-4.3T | 20/filter layer/20/10/φ10x13Px3.0T | 5-200 | 4.3 | 50 |

| FTC5-5.3T | 20/filter layer/20/10/φ10x13Px4.0T | 5-200 | 5.3 | 51 |

Note:

(1)The filter layer is selected within the range of filter accuracy according to customer requirements.

(2)Other special structures can be customized according to customer requirements.

(3)The porosity is calculated based on the 20u filter layer.

Application Fields

Power plants, food and beverage, water treatment, sand control filter for oil & gas, Brewery Equipment, coal mine industry,etc.

Application Products

Cylinder candle filter, Basket filter element, Cone filter, air fluidized plate,etc.

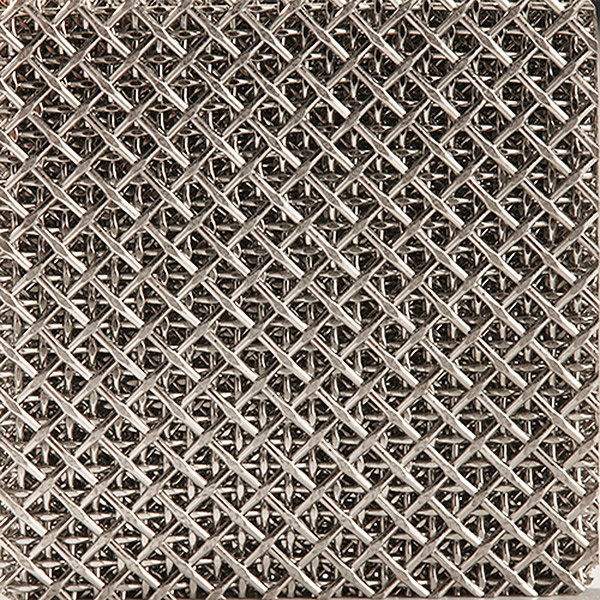

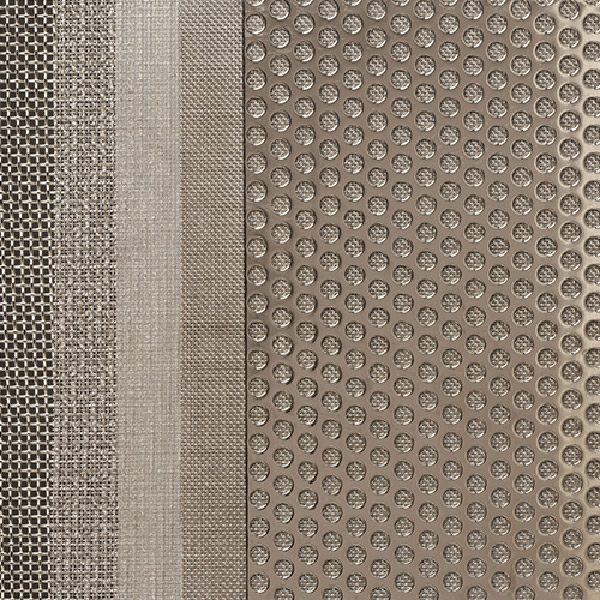

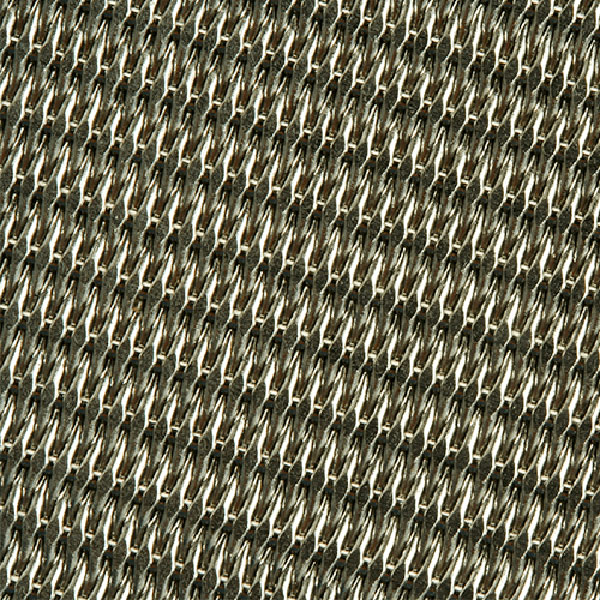

④ 2-Layer Or 3-Layer Plain Weave Dense Mesh Sintering

It is a sintered mesh made by stacking two or three layers of flat woven dense mesh with the same precision and crossed together through sintered, pressed, rolled and other processes. It has the characteristics of uniform mesh distribution and stable air permeability. Mainly used in fluidized bed, powder conveying, noise reduction, drying, cooling and other fields.

Material

SUS304, SUS316, Hastelloy, Monel, Inconel, duplex stainless steel and other special alloys.

Standard Size

500*1000mm, 600*1200mm, 1000*1000mm, 1200mm*1200mm, 1200*1500mm. Sizes within the above range can be customized according to user requirements.

Application Fields

Chemical, pharmaceutical, food, automotive, new energy industry, etc.

Application Products

Stainless Steel Candle Filter, Sintered Filter, cylinder candle filter.