-

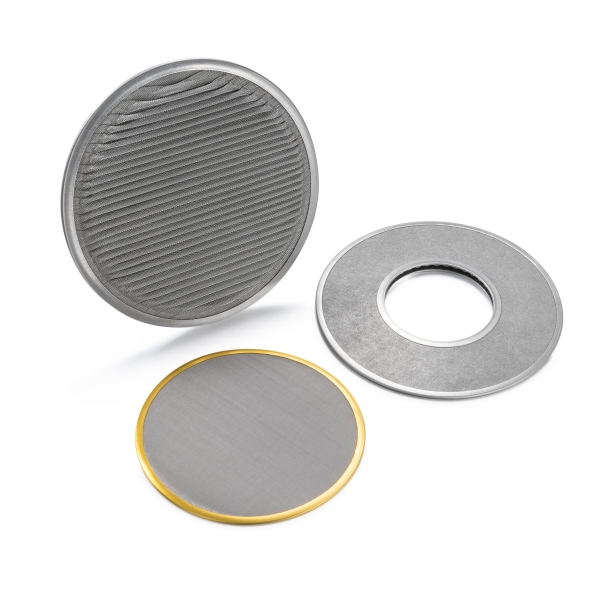

Spin Pack Filter in Metal Media

A spin pack filter in metal media is a type of filter used in various industries, particularly in polymer manufacturing processes. The solution can be oil, gas, water, grease, liquid, polymer or any type of flowing solution at any temperature. It consists of a metal wire mesh or screen that is spun into any shape, such as cylindrical, rectangular, square, oval shape or others. This pack filter is installed in the filtration system to remove impurities and particles from the solution. The metal media provides high strength and durability, allowing the filter to withstand high temperatures and pressures.

-

Stainless Steel Filter Screen

Stainless steel filter screens are a type of filtration system commonly used in various industries and applications. They are made from woven stainless steel wire mesh, sintered wire mesh in one or multiple layers, which provides excellent durability and resistance to corrosion.

These filter screens are designed to remove impurities or particles from liquids, gases, or even solid materials. They can effectively retain and separate pollutants, contaminants, or unwanted substances, while allowing the desired material to pass through.

Stainless steel filter screens are commonly used in industries such as oil and gas, water treatment, food and beverage, pharmaceuticals, chemicals, and many more. They are utilized in filtration processes, such as straining, sieving, or separating materials of different particle sizes.

-

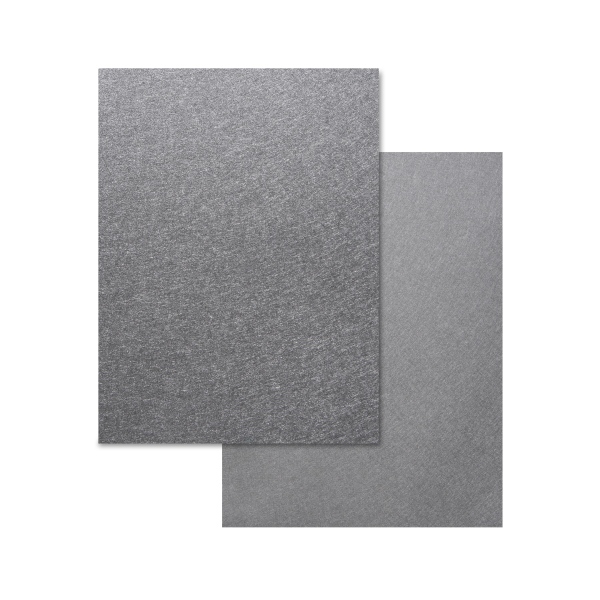

Sintered Metal Fiber for High Efficient Capability

Sintered metal fiber refers to a type of material that is produced by compacting and sintering metal fibers together. The sintering process involves heating the fibers to a high temperature, causing them to bond together to form a solid structure.

Sintered metal fiber materials have unique properties that make them suitable for various applications. Some key characteristics of sintered metal fiber include: porosity; high surface area; chemical resistance; mechanical strength; heat resistance.

Sintered metal fiber offers excellent performance in terms of filtration, porosity, chemical resistance, and mechanical strength, making it a versatile material for various industrial applications, including: Filtration; Catalysis; Acoustic insulation; Thermal management.

-

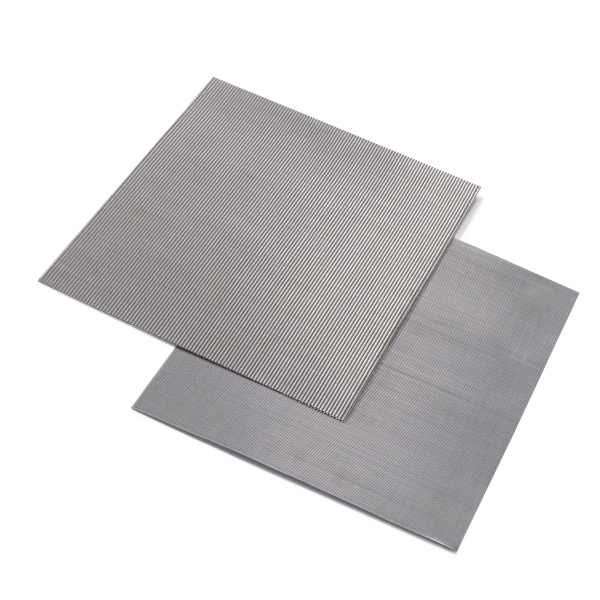

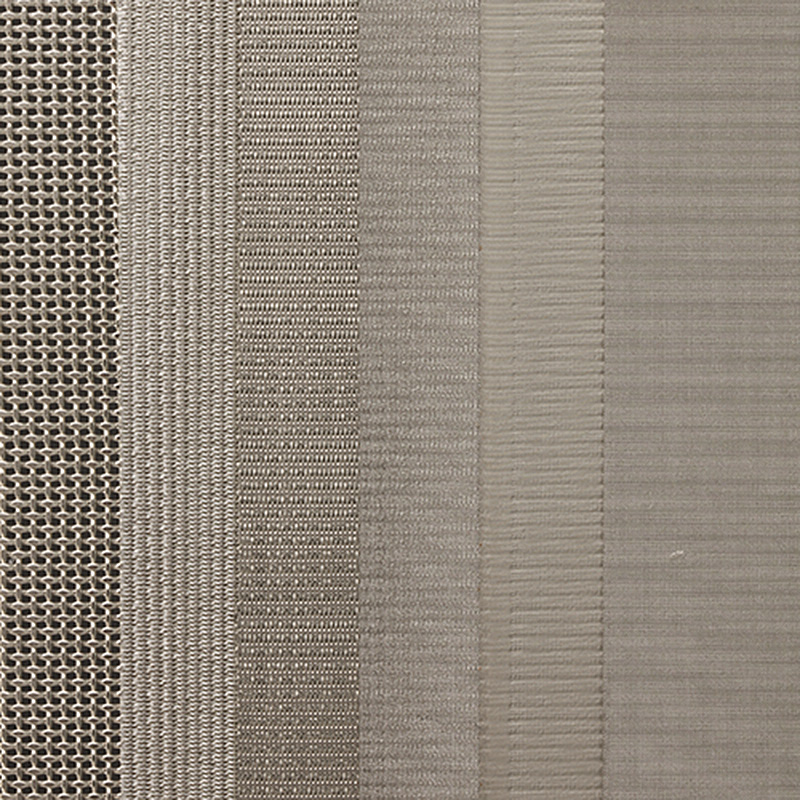

Metal Wire Mesh in Type of Plain Weave

Plain weave is a common type of weave used in metal wire mesh, which the wires are woven over and under each other in a simple crisscross pattern.Characteristics of plain weave metal wire mesh include: strong and durable; uniform aperture size; high flow and visibility; easy to cut and shape.

Common applications of plain weave metal wire mesh include: filtration; screening; insect screens; reinforcement.

When selecting plain weave metal wire mesh, factors like wire gauge, mesh size (aperture size), material type (such as stainless steel, aluminum, or brass), and specific application requirements should be considered to ensure the mesh meets the desired strength, durability, and functionality.

-

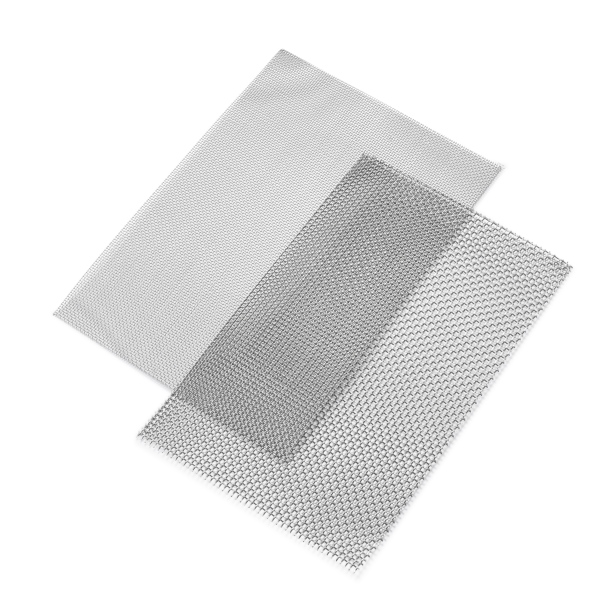

Metal Wire Mesh in Type of Dutch Weave

Dutch weave is a type of weaving pattern used in wire mesh production. It is characterized by having a greater number of wires in the warp direction compared to the weft direction. The Dutch weave pattern is commonly used in applications where finer filtration or separation is required, including chemical processing, oil and gas, food and beverage, pharmaceuticals, synthetic fiber spinning and filtration systems. Some key characteristics of Dutch weave wire mesh include: high strength; fine filtration; uniform aperture size; high flow characteristics; resistance to clogging.

Dutch weave wire mesh provides a reliable and efficient solution for applications that require fine filtration and separation, offering high strength and uniform performance.

-

Sintered Metal Wire Mesh in Multiple Layers

Sintered metal wire mesh is a type of filtration medium composed of multiple layers of woven wire mesh that have been bonded together through a sintering process. This sintering process involves heating the mesh to a high temperature, causing the wires to fuse together at their contact points, creating a porous and rigid structure.

The multiple layers in sintered metal wire mesh provide several advantages: enhanced mechanical strength; increased filtration capability; improved flow control; versatile filtration options; durability and longevity.

Sintered metal wire mesh is used in various industries, including petrochemical, pharmaceutical, food and beverage, automotive, and water treatment, chemical fiber spinning. It finds applications in filtration systems, catalyst recovery, fluidized beds, gas diffusers, process equipment, and more.

-

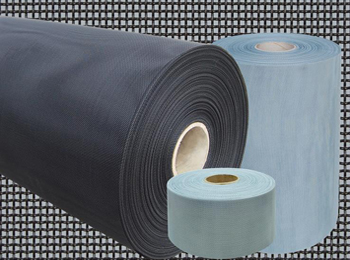

High Economic Gas-Liquid Filter Screen

A gas-liquid filter screen is a filtration device used to separate liquid droplets or mist from a gas stream. It is commonly used in industrial processes where gas and liquid phases need to be separated, such as in scrubber systems, distillation columns, and gas treatment plants.

The gas-liquid filter screen typically consists of multiple layers of woven wire mesh with specific spacing and designs to effectively capture or coalesce the liquid droplets or mist from the gas stream. These layers can be composed of different materials, such as stainless steel.

Gas-liquid filter screens are essential for maintaining the quality and efficiency of industrial processes by preventing liquid carryover, protecting downstream equipment, and complying with environmental regulations.

-

Epoxy Resin Coated Wire Mesh for Support & Protection

Epoxy resin coated wire mesh is a type of wire mesh that is coated with epoxy resin, which provides added durability and protection. The epoxy resin coating helps to prevent corrosion and increase the lifespan of the wire mesh, making it suitable for various applications.

Some common uses of epoxy resin coated wire mesh include: reinforcing concrete structures; fencing and enclosures; filtration; industrial applications.

When purchasing epoxy resin coated wire mesh, it is important to consider factors such as the mesh size, wire gauge, and the specific application requirements.

-

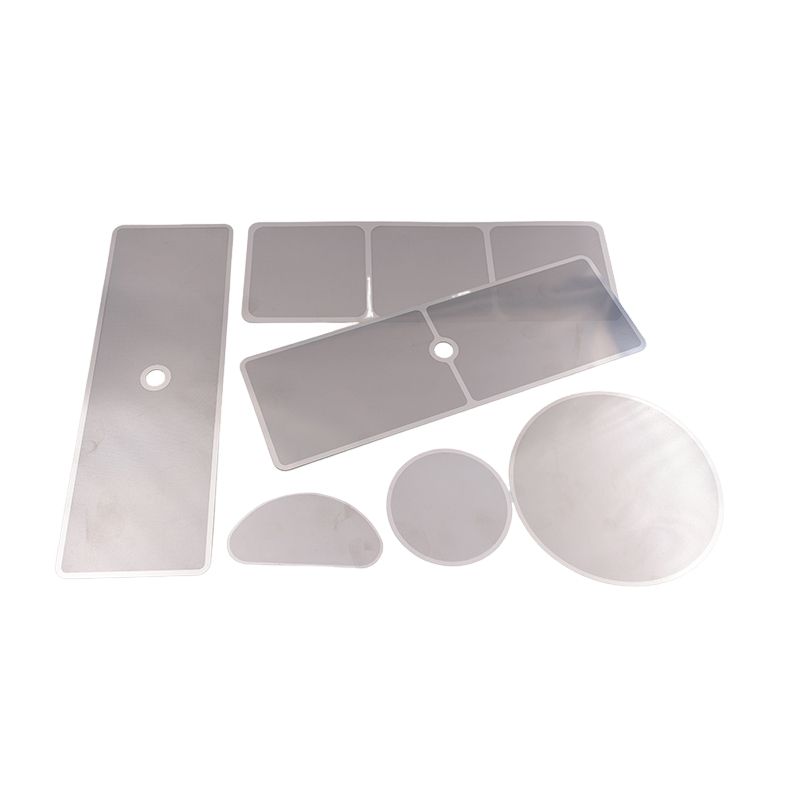

Photo Etched Film for Precision Filtration

Photo etched film, also known as photochemical etching or photo etching, is a manufacturing process used to produce precise metal parts with intricate patterns or designs, which is commonly used in the process of high quality filament spinning, in order to avoid the clog of spinneret capillaries.

Photo etched film offers several advantages in manufacturing compared to traditional methods like stamping or laser cutting. It allows for high precision, intricate patterns, and complex designs with tight tolerances. It is also a cost-effective method for producing small to medium-sized production runs. Furthermore, it eliminates the need for expensive tooling and reduces the lead time for prototyping and production.