The molten PET PA PP high polymer needs to be filtered before the chemical fiber spinning to remove the impurity and gel particles entrained in the melt to prevent the plugging of the spinneret hole; when the melt polymer flows through the spin pack screen layer, resistance is generated, so that the melt Friction generates heat, the temperature rises, and the rheological properties of the melt are improved. At the same time, the melt is fully mixed to prevent viscosity differences between the melts; the melt is evenly distributed to each small hole of the spinneret; with the increase of the use time of the spin pack filter, the impurities in the mesh pack filter layer will increase, and the pressure of the assembly will gradually increase. The pressure increase speed is fast, and the service life of the assembly is short. When the assembly rises to a certain pressure, it is necessary to replace the assembly in time, otherwise, the metering pump is crushed, or the spinneret is deformed, or leakage occurs.

The molten PET PA PP high polymer needs to be filtered before the chemical fiber spinning to remove the impurity and gel particles entrained in the melt to prevent the plugging of the spinneret hole; when the melt polymer flows through the spin pack screen layer, resistance is generated, so that the melt Friction generates heat, the temperature rises, and the rheological properties of the melt are improved. At the same time, the melt is fully mixed to prevent viscosity differences between the melts; the melt is evenly distributed to each small hole of the spinneret; with the increase of the use time of the spin pack filter, the impurities in the mesh pack filter layer will increase, and the pressure of the assembly will gradually increase. The pressure increase speed is fast, and the service life of the assembly is short. When the assembly rises to a certain pressure, it is necessary to replace the assembly in time, otherwise, the metering pump is crushed, or the spinneret is deformed, or leakage occurs.

The selection of suitable filter components is very critical for spinning, and ideal particle filter media is particularly important. In the process of spinning development, it is also the process of finding an ideal shear filter medium. Many known filter materials include sea sand, metal shavings, glass beads, sintered porous metal plates, and irregularly shaped metal particles.

In addition to being inexpensive, the ideal filtering medium must have and must maintain high porosity at the pressures encountered during melt polymer filtration. In order to maintain high porosity, a bed of the particles of most hot polymers is a tendency to form gel which accumulates in and reduces the filtration efficiency of filter media. Thus, the particulate metal filtering material must not catalyze or otherwise contribute to gel formation.

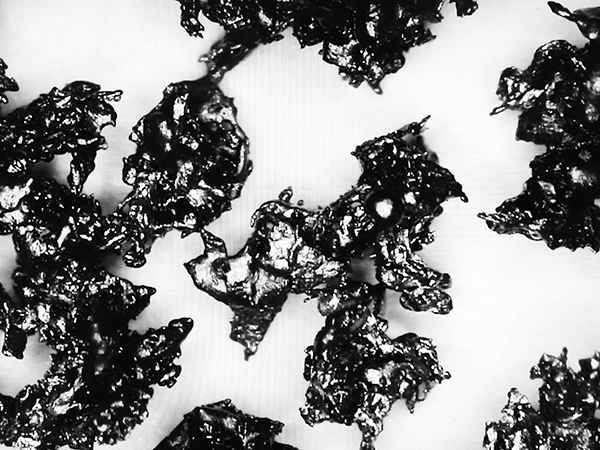

It is more available to get sea sand, but it is extremely brittle with the result that the development of fine particles tends to obstruct the capillaries in the spinnerets. Additionally, the specific surface area of sea sand is substantially less and less percentage of porosity for any given pack filter volume, therefore the pack pressure shall increase sharply. Stainless metal powder which is prepared under specific conditions exhibits an extremely irregular surface which accordingly low apparent density, tends to enhance its filtration efficiency; under operation pressures, it exhibits both the apparent density and enhance resistance to compressibility for optimum filtration efficiency with little or no particle deformation and collapse.

Post time: Aug-29-2018