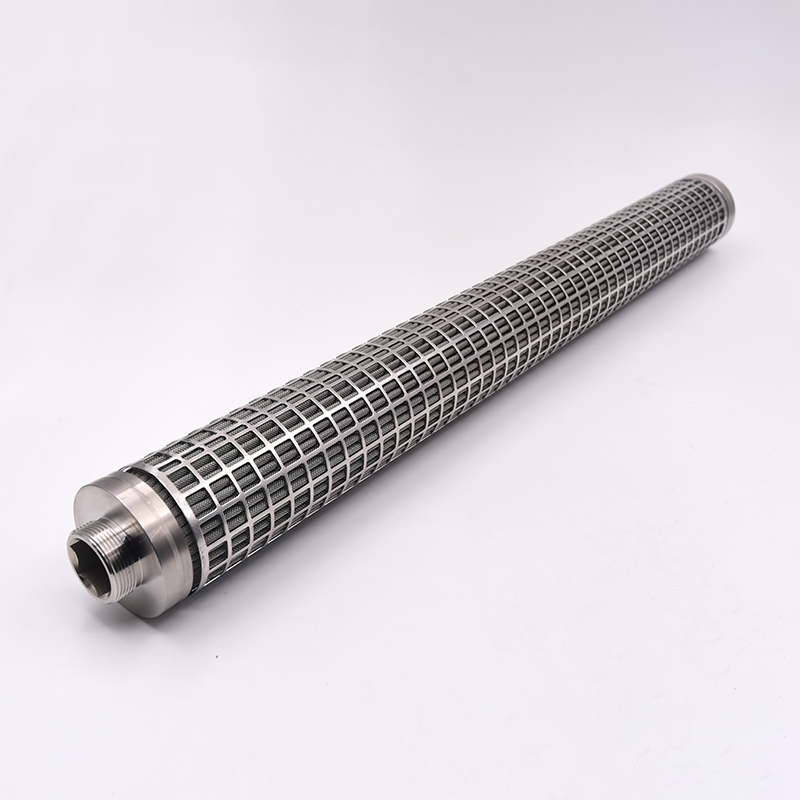

Melt Polymer Candle Filter for High Viscosity Substances Filtration

Melt Polymer Candle Filter

Melt filter element is an all-metal filter element welded by argon arc welding. The filter layer adopts a multi-pleat structure folding process, with uniform pore size distribution and increased filtering area. The metal pleated filter is made entirely of stainless steel, with no leakage or medium shedding. In high pressure environments, the stainless steel pleated filter adopts a skeleton design. The inner and outer skeleton greatly enhances the pressure resistance of the metal pleated filter element. The main filter layer of Pleated Filter mainly uses two materials:stainless steel wire mesh and stainless steel Sintered fiber . Stainless steel wire mesh is woven from stainless steel wire. Its pleated filter has the characteristics of smooth pores, easy cleaning, high temperature resistance, corrosion resistance, no wire mesh falling off, and long filtration cycle. Stainless steel sintered fiber is a porous deep filter material made of stainless steel fibers sintered at high temperature. Its pleated filter has the characteristics of high porosity, good air permeability, strong dirt holding capacity, and strong regeneration ability.

Melt filter element is a filtration device widely used in the chemical fiber industry for polymer melt and other high-viscosity substances. Its function is to remove solid impurities such as carbonized particles and metal oxides in the melt, improve the purity of the melt, provide qualified raw materials for downstream processes, and ensure the normal operation of the melt filter.

Technical Characteristics

1. Resistant to high temperature, high pressure and chemical corrosion.

2. Excellent breathability, large dirt holding capacity, high strength, good sealing, long life, and can be cleaned and reused for repeated use.

3. The folded filter area is 3-5 times that of the cylindrical type.

4. Working temperature: -60-500℃.

5. The maximum pressure difference the filter element can withstand: 10MPa.

Product Typical Application Parameters

1. Working pressure: 30Mpa.

2. Working temperature: 300℃.

3. Dirt holding capacity: 16.9~41mg/cm².

Product Connection Method

Standard interface (such as 222, 220, 226) quick interface connection, threaded connection, flange connection, tie rod connection, special customized interface.

Application Areas

1. Petrochemical: Refining, chemical production and separation and recovery of intermediate products.

2. Metallurgy: used for filtration of hydraulic systems of rolling mills and continuous casting machines.

3. Textile: Purification and uniform filtration of polyester melt during the drawing process.

4. Electronics and pharmaceuticals: pre-treatment and filtration of reverse osmosis water and deionized water, pre-treatment and filtration of cleaning fluid and glucose.

5. Thermal power and nuclear power: purification of lubrication systems, speed control systems, bypass control systems of gas turbines and boilers, purification of water supply pumps, fans and dust removal systems.

More Product