High Economic Gas-Liquid Filter Screen

Gas-Liquid Filter Screen

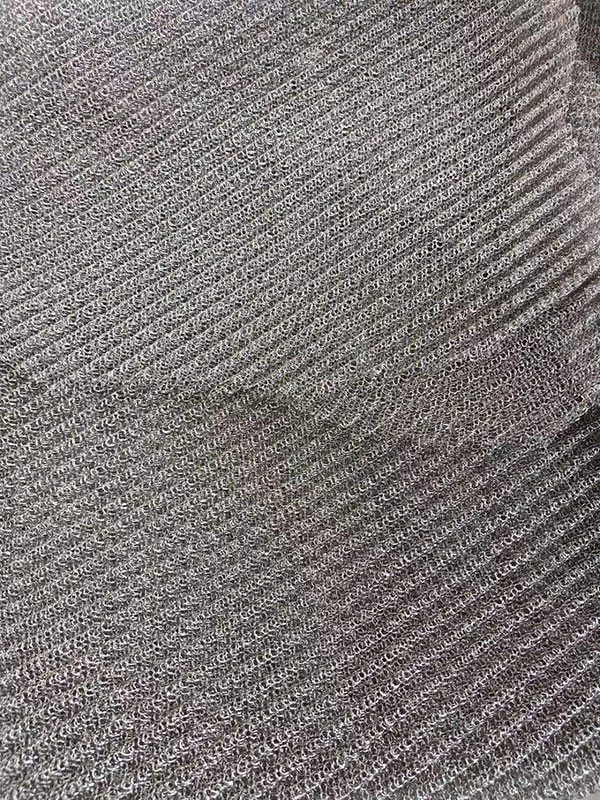

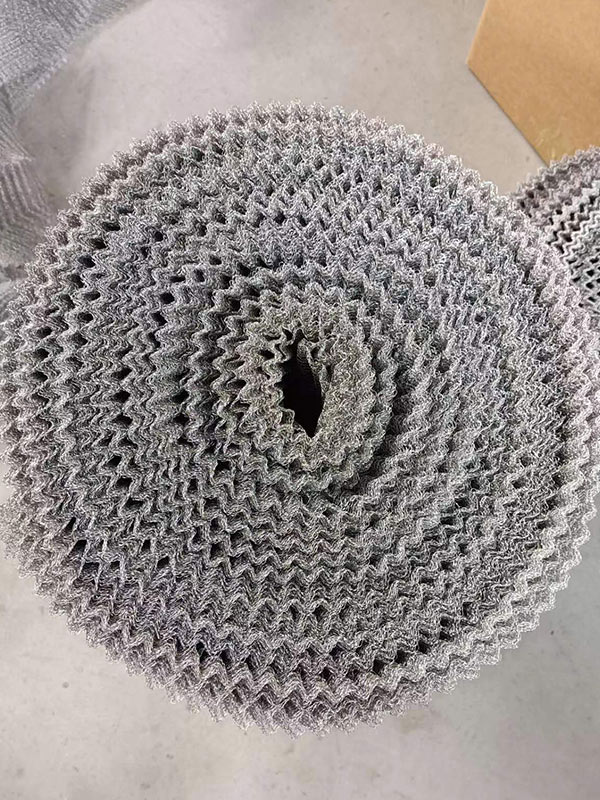

A special woven wire mesh improved by using the traditional method of knitting with knitting needles. The wire used for weaving is generally φ0.08-φ0.50mm round wire or pressed flat wire, and the wire diameter ≤ φ0.30mm can be multi-strand Braided, the form of multi-strand braiding can also be braided with metal wire and fiber yarn. According to the needs, it can be pressed and rolled on the screen to form corrugated shapes of various styles and specifications. The rolled and formed wave-shaped nets are crossed and stacked with each other at the correct angle. The multi-layer folding expansion is based on different densities and apertures, so that the flow direction can be changed multiple times when the object passes through, increasing its efficiency.

Advantages

①Low resistance, repeatable cleaning, high economy.

②Acid and alkali resistance, high temperature resistance, high strength.

③Safe, strong and long service life.

Gas-Liquid Filter Screen Technical Parameters

① Wire diameter range: 0.07mm-0.55mm (regular wire diameter:0.20mm-0.25mm).

② Hole Size: there are 2×3mm, 4×5mm, 12×6mm, etc. the opening size can be finely adjusted according to customer requirements.The opening form is a cross arrangement of large holes and small holes (the size of the holes in the length direction is the same, but the width is different).

③ Surface conditions of gas-liquid filter screens: flat mesh surface and corrugated mesh surface (the width and depth of the corrugations have different specifications).

④ The width range of gas-liquid filter screens: 40mm、80mm、100mm、150mm、200mm、300mm、400、500mm、600mm、800mm、1000mm、1200mm、1400mm, etc.

Gas-Liquid Filter Screen Specification Standards

(1) Standard specifications

| 40-100 | 60-150 | 105-300 | 140-400 | 160-400 |

(2) High-efficiency specifications

| 60-100 | 80-100 | 80-150 | 150-300 | 200-400 |

(3) High Penetration Specifications

| 20-100 | 80-100 | 70-400 | 170-560 | 170-600 |

The above are the standard specifications of the factory, for other specifications, please consult for customization.

Material Of Gas-Liquid Filter Screen

Various types of stainless steel wire, galvanized iron wire, bronze wire, nickel wire, titanium wire, alloy wire, etc. (with attached pictures).

Application Fields

Process wire mesh demister filter pads, filter screens for gas-liquid separation, gas-water separation, oil-water separation, etc. various filter elements on engines such as automobiles and tractors, sealing and shock absorption (avoidance) in automotive parts Shock, noise reduction and exhaust purification components, shielding devices for electronic and electrical products to prevent electromagnetic interference.