Filtration System for Oil Filtration

Oil Filter Truck

The LUCB series oil filter truck produced by our company has the features with reliable performance, compact structure, beautiful appearance, easy maintenance and use, also has the advantages of high precision and low noise, the filters in the fine filter can be freely selected in 3, 5, 10, 20 and 30μm according to the different needs of customers, Only change the filters with different filtration accuracy can achieve the filtration effect of different precision, and the oil filter truck only filters out the pollution in the oil, and has no impact on the technical indicators of the oil.

Technical Parameters

|

Model |

Nominal flow (L/min) |

Coarse filtration accuracy (µm) |

Fine filtration accuracy (µm) |

Initial pressure loss (Mpa) |

Magnet suction (N) |

Power (kw) |

Voltage (V) |

Weight (kg) |

|

LUC-16×*# |

16 |

100 |

3 5 10 20 30 |

<0.02 |

2 |

0.37 |

380 |

60 |

|

LUC-40×*# |

40 |

0.75 |

90 |

|||||

|

LUC-63×*# |

63 |

1.1 |

100 |

|||||

|

LUC-100×*# |

100 |

1.5 |

110 |

|||||

|

LUC A/B-16×*# |

16 |

0.37 |

||||||

|

LUC A/B -40×*# |

40 |

0.75 |

||||||

|

LUC A/B -63×*# |

63 |

1.1 |

||||||

|

LUC A/B -100×*# |

100 |

1.5 |

User-supplied accessories and wearing parts

|

Model |

Spares name |

|||

|

Coarse filter model |

Fine filter model |

Skeleton oil seal(3) HG4-692-67 |

PVCReinforced hoses(L 2mm) ID mm |

|

|

LUC-16×* |

CWU-16×100-J |

CZX-16×*# |

20×40×10 |

Oil absorptionReturn oilΦ19 |

|

LUC-40×*/ LUCB-40×* |

CWU-40×100-J |

CZX-40×*# |

25×45×10 |

Oil absorptionΦ32 Return oilΦ25 |

|

LUC-63×*/ LUCB-63×* |

CWU-63×100-J |

CZX-63×*# |

25×45×10 |

Oil absorptionΦ32 Return oilΦ25 |

|

LUC-100×*/ LUCB-100×* |

CWU-100×100-J |

CZX-100×*# |

30×50×10 |

Oil absorptionΦ32 Return oilΦ25 |

|

Spares name |

||||||

|

Model |

Coarse filter model |

Three-stage filter cartridge |

Skeleton oil seal(3) HG4-692-67 |

PVC Reinforced hoses(L 2mm) ID mm |

||

|

Primary strainer filter First Filter Model |

Primary strainer filter Second Filter Model |

Fine filter model |

||||

|

LUCA-16×* |

CWUA-16×100-J |

CXXA1-16×80 |

CXXA2-16×50 |

CZXA-16×*# |

20×40×10 |

Oil absorption Return oilΦ19 |

|

LUCA-40×* |

CWUA-40×100-J |

CXXA1-40×80 |

CXXA2-40×50 |

CZXA-40×*# |

25×45×10 |

Oil absorptionΦ32 Return oilΦ25 |

|

LUCA-63×* |

CWUA-63×100-J |

CXXA1-63×80 |

CXXA2-63×50 |

CZXA-63×*# |

25×45×10 |

Oil absorptionΦ32 Return oilΦ25 |

|

LUCA-100×* |

CWUA-100×100-J |

CXXA1-100×80 |

CXXA2-100×50 |

CZXA-100×*# |

30×50×10 |

Oil absorptionΦ32 Return oilΦ25 |

Note:

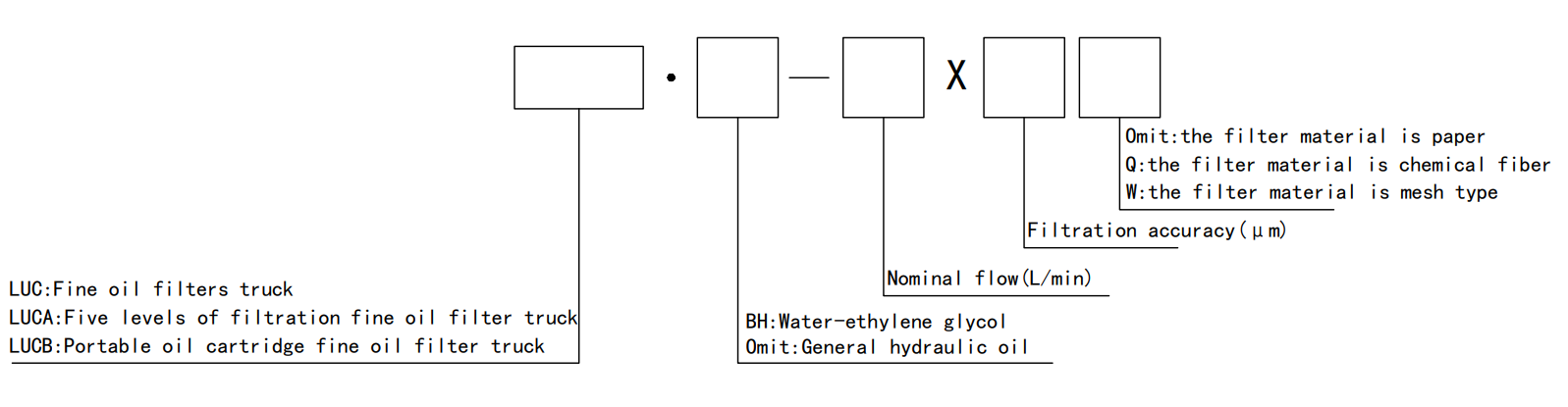

(1) * indicates filtration accuracy, # indicates filter material. Omitted is paper filter material, Q is glass fiber material, and W is mesh filter material.

(2) In order to ensure the rated flow of the oil filter truck and its normal use, the inner diameter of the user's self-distribution oil pipe should comply with the specifications in the table above: and note that the oil suction pipe must not be flattened during work to avoid damage to the oil pump, and the oil suction height difference is <500mm.The oil suction hose must not be lengthened; the oil return hose must not be longer than 8m.

(3) Refers to the oil pump shaft seal.

Oil filter truck use and maintenance

(1) When starting the oil filter truck, care should be taken not to reverse the rotation of the oil pump to avoid blowing out the oil pump shaft seal and inhaling air.

(2) During the use of the oil filter truck, the oil pump may inhale air, affecting the flow of the oil pump. In order to achieve the rated flow rate of the oil filter truck and ensure the normal operation of the fine filter element, the exhaust valve should be opened in time to drain the air in the filter cartridge (i.e. After the exhaust valve discharges oil), close the exhaust valve promptly after exhausting the air.

(3) After the oil filter truck has been used for a period of time, if the surface of the coarse filter element is seriously blocked by pollutants and the oil suction is not smooth, causing excessive noise from the oil pump, the machine should be stopped and the filter element should be taken out for cleaning.

(4) After the fine filter element is used for a period of time, it is easy to be gradually blocked by pollutants, causing the pressure of the filter cartridge to increase. When the pressure reaches 0.4Mpa, the fine filter element needs to be replaced in time.

(5) The oil suction and oil discharge hoses used should be kept clean at all times.

(6) If the oil filter truck cannot pump out oil, please check and confirm

a. Is the oil pump steering correct?

b. Whether the sealing of each component between the fuel tank and the oil suction port is reliable, whether the oil suction port is away from the oil surface or the oil has been sucked out;

c. Is the coarse filter element clogged?

(7) The flow of oil filter trucks has been significantly reduced, please check and confirm:

a. Are the coarse and fine filter elements seriously clogged?

b. Whether the oil pump shaft oil seal is worn or blown out due to reverse rotation.

(8) The filtration pressure suddenly drops, please check whether the fine filter element is broken down.