In industrial production, oil is an indispensable and important element. Oil filtration falls into two categories:

In industrial production, oil is an indispensable and important element. Oil filtration falls into two categories:

1. Crude oil

Crude oil is a complex mixture containing various hydrocarbons, sulfides, nitrogen compounds, etc., which can cause damage to equipment and the environment. Therefore, it is necessary to filter crude oil.

The purpose of crude oil filtration is to remove impurities, improve the purity of crude oil, and ensure the normal operation of subsequent processing. At the same time, the filtered crude oil can also reduce the corrosion and wear of the equipment and prolong the service life of the equipment.

2. Refined oil

Refined oil is produced and processed from crude oil, such as lubricating oil, hydraulic oil, fuel oil, etc. These oils can become contaminated during use, causing wear and failure of equipment.

The content that needs to be filtered in the oil mainly includes suspended solids, particulate matter, metal powder, harmful chemicals, microorganisms, etc. These impurities will affect the lubrication effect of the equipment, accelerate the wear of the equipment, and even cause the failure of the equipment. Therefore, oil filtration has become an important means to ensure the normal operation of equipment

The principle of oil filtration is mainly to separate suspended matter such as impurities, particulate matter, and metal powder in the oil through the filter medium. This process mainly depends on the choice of filter media and filter design. Commonly used filter media include filter paper, filter screen, filter cotton, etc., which have different filtration accuracy and pressure resistance.

There are many types of oil filtration, including mechanical filtration, chemical filtration and biological filtration. Mechanical filtration is mainly to filter out large particles, impurities and other suspended matter in the oil through filter media such as filter screen or filter paper. Chemical filtration is to filter out harmful chemicals in oil through chemical methods such as adsorption, precipitation, and ion exchange. Bio-filtration is to filter out microorganisms and odors in oil through biological substances such as biological enzymes or activated carbon.

In practical applications, oil filtration needs to consider different working conditions and requirements. For example, under the condition of high viscosity and high load, it is necessary to choose a filter material with high strength and high temperature resistance; while for the condition of low viscosity and low load, it is necessary to choose a filter material that pays more attention to purity. In addition, for different types of oil products, it is also necessary to choose suitable filtration methods and products.

Oil filtration requires consideration of the following factors:

Filtration fineness: Selecting a suitable filtration fineness can effectively remove impurities in the oil, and at the same time, excessive filtration will not lead to a decline in oil quality.

Pressure resistance: oil filtration products need to have sufficient pressure resistance to withstand the filtration process under high pressure difference.

Chemical Compatibility: Oil contains a variety of chemicals, and filtration products need to be compatible with these chemicals without chemical reaction or corrosion.

Anti-pollution ability: Filtration products need to have good anti-pollution ability, which can effectively remove impurities in oil, and at the same time, it is not easy to be blocked or polluted.

Convenience of maintenance: The convenience of maintenance of filtration products is also a factor that needs to be considered, including the difficulty and cost of replacing filter elements and cleaning filter sheets.

In short, oil filtration is an important link to ensure industrial production. By selecting the appropriate oil filtration products, impurities in the oil can be effectively removed, the purity of the oil can be improved, and the normal operation of subsequent processing can be guaranteed. At the same time, the filtered oil can also reduce the corrosion and wear of the equipment and prolong the service life of the equipment.

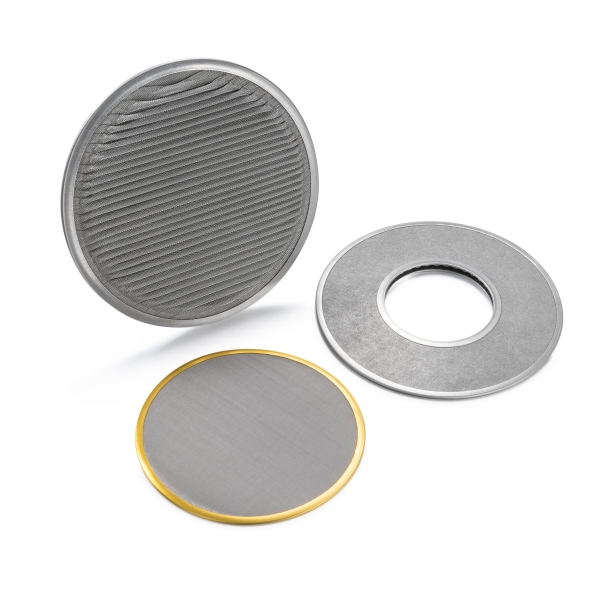

Our company provides oil filtration products such as filters, filter elements, spin pack filters, Pack screens, gaskets, wire mesh demisters, Wire Mesh Corrugated Packing, etc. These products have different filtration accuracy, pressure resistance and service life , need to be selected according to different working conditions and requirements. We can customize products of various specifications, sizes and filtration precision according to customer needs.